In recent years, the demand on electric motors, moving in more than one degree of freedom or so-called multi-degrees of freedom (MDOF), has witnessed a significant increase. This paradigm shift is primarily due to the emergence of new applications that require large tilt angles, greater force, and more uniform fluxes; such applications include automotive powertrains, biomedical instrumentations, and oil and gas robots. Unfortunately, designing MDOF electric motors is an uncharted territory for most motor and actuator companies. Such an undertaking necessitates not only an experienced engineer with a deep understanding of motor design, but also a state-of-art motor simulation software capable of handling MDOF motion. Most commercial electromagnetic and motor simulation software packages can handle only one degree of freedom. Because EMS is coupled to SolidWorks Motion, it is capable of handling MDOF motion.

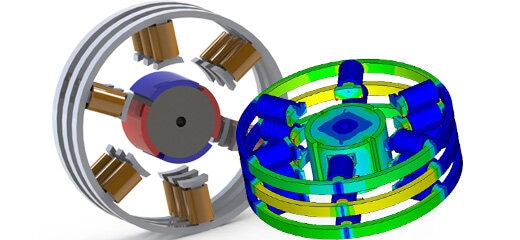

In this webinar, we will take-you-by-the-hand and walk you through the various steps to create a SolidWorks Motion study with MDOF and couple it to EMS. We shall demonstrate, to you, the procedure on a permanent magnet spherical motor published in the journal Actuators in 2021. The motor is made of a 4-pole permanent magnet rotor and a 3-block stator having 18 coils. Breathtaking results will be presented, and various findings will be discussed.