Motor eccentricity is a matter of great importance to manufacturers due to a range of factors. In fact, it can arise from manufacturing tolerances, thermal expansion, and mechanical stress, and has a significant effect on motor performance. This impact includes increased vibration, elevated noise levels, decreased efficiency and power output. Moreover, unbalanced motors endure heightened temperatures, resulting in increased losses and a potential decrease in their operational lifespan.

To mitigate the effects of eccentricity, motor manufacturers take measures to minimize and control eccentricity during the manufacturing process. These measures include strict quality control, precise machining techniques, and accurate alignment of motor components.

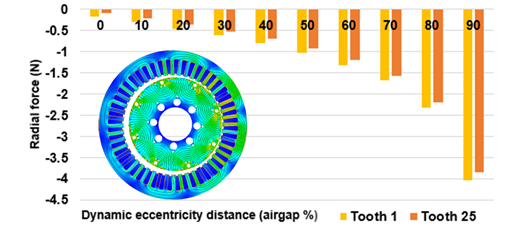

In this webinar, we will analyze the effect of different eccentricity types (static-dynamic and mixed) on the Nissan Leaf performance based on our virtual prototyping EMWorks2D software. We will parametrize different eccentricity inputs for each type, at on load condition, and see the motor behavior under these varying conditions. The electromagnetic performance such as the torque, the radial force and the flux density distribution, will all be evaluated and compared based on finite element analysis.