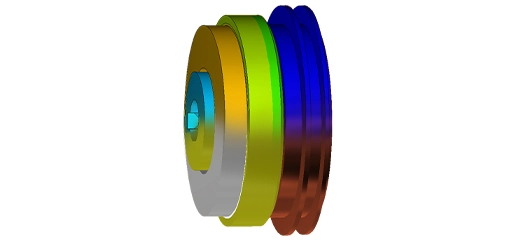

Electromagnetic simulation plays a pivotal role in the design and optimization of magnetic clutches, offering engineers invaluable insights into crucial performance parameters. By accurately modeling the interaction between the stator and rotor, designers can predict magnetic force variations across different air gap distances. This predictive capability allows for fine-tuning of the clutch's efficiency and reliability, ensuring optimal performance under varying conditions. Additionally, coupling electromagnetic simulations with multiphysics modules enables the analysis of temperature distribution resulting from the Joule effect. This comprehensive approach aids in preventing overheating issues, enhancing reliability, and extending the lifespan of the clutch.

EMWorks Inventor is an advanced electromagnetic FEM simulation tool, coupled with multiphysics modules, empowers designers to streamline the design process, leading to the development of innovative and optimized clutch systems for various applications.

Leveraging EMS facilitates iterative refinement of clutch designs, considering factors such as size and weight, to achieve compact yet high-performing solutions. In essence, EMS for Autodesk Inventor empowers designers to streamline the design process, leading to the development of innovative and optimized clutch systems for various applications.