Induction heating stands as a highly efficient method for warming both ferromagnetic and non-ferrous materials. Widely utilized in household appliances like induction cookers, as well as diverse industrial applications such as induction furnaces, hardening, welding, brazing, and tempering, its versatility is evident. This technique's appeal lies in its rapidity, precision, cleanliness, safety, efficiency, and minimized energy consumption. Despite significant advancements, there remains room for enhancing induction heating devices' efficiency.

Crucial design considerations include the material properties and temperature dependency of the heated object, coil shape and design, coil distance and positioning concerning the heated object, and the magnitude and frequency of excitation. Addressing these parameters can curtail costly prototyping endeavors, inching closer to the ideal of "zero prototyping."

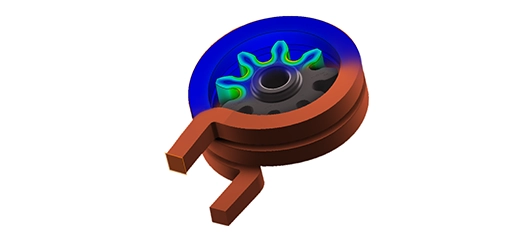

In our upcoming webinar, we'll demonstrate how our virtual prototyping tool, EMS inside Autodesk Inventor, facilitates the analysis and optimization of induction heating equipment design. We'll showcase electromagnetic and thermal results to aid your understanding and optimization efforts.