Induction heating is an efficient technique to heat up ferromagnetic and non-ferrous materials. It is largely employed in home appliances, such as induction cookers, and other various industrial applications like induction furnace, induction hardening, welding, brazing, and tempering.

The diversity of induction heating applications is mainly attributed to its speed, precision, cleanness, safety, efficiency, and reduced energy consumption. Despite the accomplished progress, there is still an opportunity for improvement to build an efficient induction heating device.

The material properties of the heated object and its temperature dependence, the shape and design of the coil, the distance, and the position of the coil with respect to the heated object, the magnitude and frequency of the excitation are key design parameters that should be considered to minimize costly prototyping and eventually achieve a paradigm for “zero prototyping”.

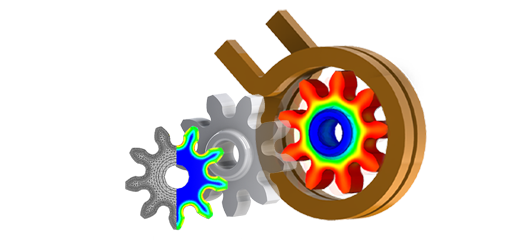

In this webinar, we will show you how to use our virtual prototyping tool EMS to analyze and optimize the design of your induction heating equipment and present our electromagnetic and thermal results.