"Thank you for giving me the opportunity to use the ElectroMagneticWorks add-in on SolidWorks. It has been amazing to experiment with.

The simplicity and intuitiveness of the software made it a very rewarding experience when simulating my model for the purpose of writing my dissertation to which I have given full credit to EMS. Although it might seem intimidating to use at first, the tutorials proved to be the ultimate savior.

I have truly learned a lot from this software. Knowledge that are taught in the book were only found to be true to a certain extent and it has gave me a new insight in dealing with electromagnetic designs which I have included in my dissertation.

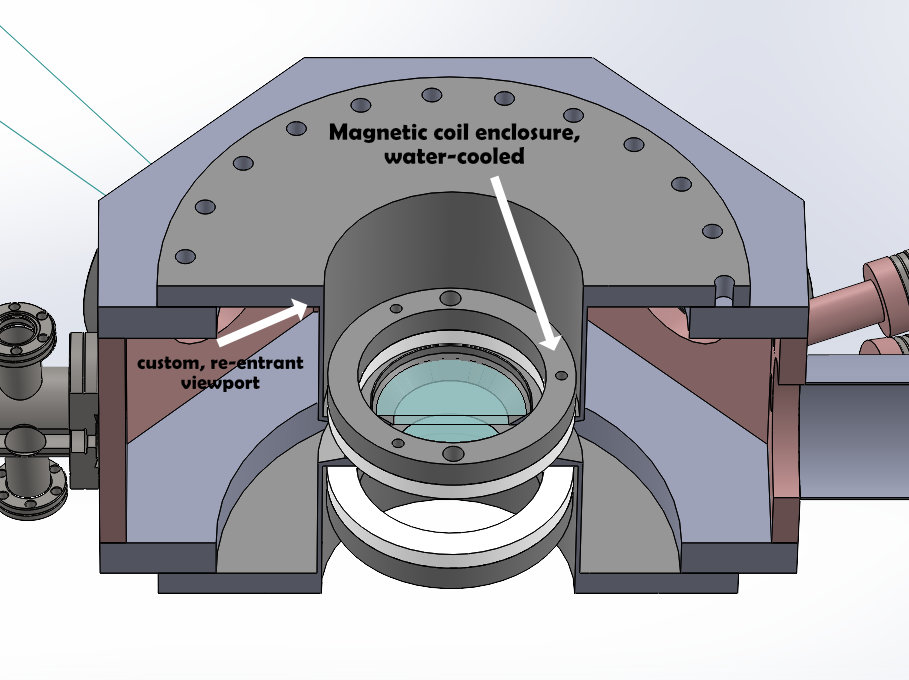

Over the past year, I’ve had the opportunity to use EMWorks to aid in my study of magnetic coils on our apparatus. With this tool, we can model many types of coil designs, such as using thin magnet wire, and water cooling it, or instead going with hollow-core type of wiring (with finite diameters and realistic spiraling modeled in SW) and running cool water through that. We can then see our magnetic field profiles all around the coils, and of course in the center of our Helmholtz configuration, where we would like to ensure very flat magnetic fields. In a complex environment such as a cold-atom experiment, I want to ensure that the vacuum chamber geometry itself would not impede our ability to ramp up and down the current on the magnetic coils, due to eddy currents. By tuning the materials, and in real-time designing components the way they would be engineered, we will be able to fine-tune our apparatus to our needs and constraints. In the future, we will continue to evaluate the eddy currents present in our system as we try different parameters for our magnetic field control (see image).

One great aspect to continue expanding on would be the video tutorials highlighting the many ways to get students started on using EMWorks for their applications. As a beginner, setting up the basic parameters like the “air geometry” was made simpler by watching someone show those steps specifically through SolidWorks.

(The image shows a cut-away view from our new vacuum chamber. We want to verify the compatibility of a new magnetic coil system with the chamber. )

By visiting or using this website you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.View cookies details

Stanley Chun Wee - Student

University of Western Australia"Thank you for giving me the opportunity to use the ElectroMagneticWorks add-in on SolidWorks. It has been amazing to experiment with.

The simplicity and intuitiveness of the software made it a very rewarding experience when simulating my model for the purpose of writing my dissertation to which I have given full credit to EMS. Although it might seem intimidating to use at first, the tutorials proved to be the ultimate savior.

I have truly learned a lot from this software. Knowledge that are taught in the book were only found to be true to a certain extent and it has gave me a new insight in dealing with electromagnetic designs which I have included in my dissertation.

Keep up the good work."

Bhagwan Singh - Student

Rice UniversityOver the past year, I’ve had the opportunity to use EMWorks to aid in my study of magnetic coils on our apparatus. With this tool, we can model many types of coil designs, such as using thin magnet wire, and water cooling it, or instead going with hollow-core type of wiring (with finite diameters and realistic spiraling modeled in SW) and running cool water through that. We can then see our magnetic field profiles all around the coils, and of course in the center of our Helmholtz configuration, where we would like to ensure very flat magnetic fields. In a complex environment such as a cold-atom experiment, I want to ensure that the vacuum chamber geometry itself would not impede our ability to ramp up and down the current on the magnetic coils, due to eddy currents. By tuning the materials, and in real-time designing components the way they would be engineered, we will be able to fine-tune our apparatus to our needs and constraints. In the future, we will continue to evaluate the eddy currents present in our system as we try different parameters for our magnetic field control (see image).

One great aspect to continue expanding on would be the video tutorials highlighting the many ways to get students started on using EMWorks for their applications. As a beginner, setting up the basic parameters like the “air geometry” was made simpler by watching someone show those steps specifically through SolidWorks.

(The image shows a cut-away view from our new vacuum chamber. We want to verify the compatibility of a new magnetic coil system with the chamber. )