About induction heating

Induction heating represents a fascinating blend of physics and practical application, enabling efficient and rapid heating of conductive materials through electromagnetic induction. This process leverages the eddy currents induced in the material by a high-frequency alternating magnetic field, generated by an AC current passing through a coil. The phenomenon, known as the Joule effect, results in the heating of the conductor due to the resistance it offers to the flow of these eddy currents.

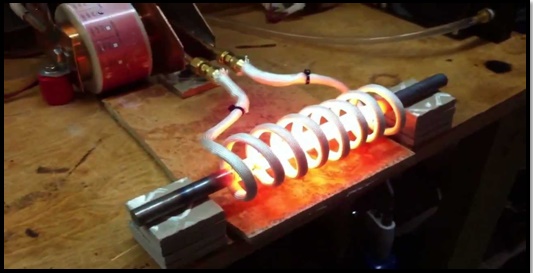

Figure 1- A conducting rod is heated using induction

Induction heating contrasts significantly with conduction heating, where the object must be in direct contact with the heat source. Instead, induction allows for the internal generation of heat within the object, enabling quicker heating processes. This technology finds applications in various fields, from industrial furnaces and welding to domestic cooking appliances.

Induction Cooking: A Case Study

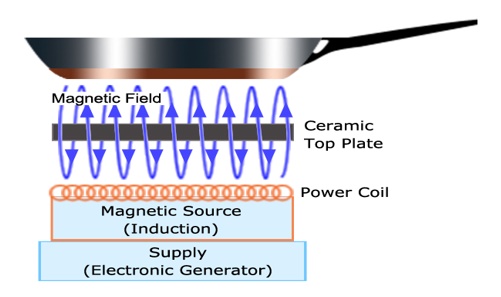

In induction cooking, a vessel typically made of ferromagnetic material is heated through electromagnetic induction, a stark contrast to traditional heating by flame or electric coil. This method achieves a swift rise in the vessel's temperature. As demonstrated in figure 2, a copper coil is situated beneath the vessel, separated by a ceramic layer known as the top plate. This arrangement allows for efficient and focused heating, leveraging the principles of induction to provide rapid and uniform temperature increases directly in the cooking vessel.

Figure 2- Elements of induction cooking appliance

When a high-frequency AC current flows through the induction coil, it induces significant eddy currents in the cooking vessel. These currents, combined with the vessel's surface resistance, generate rapid heat, facilitating cooking. The choice of material for the cooking vessel is crucial; ferromagnetic materials such as cast iron or certain stainless-steel grades are highly recommended over aluminum or copper. However, aluminum or copper vessels can still be used if modified with a ferromagnetic disk acting as a hot plate. Ferromagnetic materials offer two key benefits for induction cooking:

Increased Electrical Resistance: Ferromagnetic materials exhibit higher electrical resistance compared to pure conductors like copper or aluminum. This higher resistance leads to greater heat generation, making cooking more efficient.

Reduced Skin Depth: The skin depth in ferromagnetic materials is less than that in pure conductors, contributing to higher surface resistance. This results in more effective Joule heating, whereby the vessel heats up more quickly and uniformly.

These advantages underline why ferromagnetic materials are the preferred choice for induction cooking vessels, optimizing the efficiency and effectiveness of the heating process.

Why induction induction-based cooking attractive?

Induction cooking is appealing for several key reasons, making it a preferred choice for modern kitchens:

Energy Efficiency: Induction cooking stands out for its remarkable energy efficiency. A study by the U.S. Department of Energy in 2001 highlighted that induction cookers achieve an energy transfer efficiency of 84%, which is significantly higher than the 74% efficiency of smooth-top non-induction electrical units. This high efficiency means less wasted energy and lower utility bills.

Consistent and Uniform Heating: Unlike traditional cooking methods, induction cooking offers consistent and uniform heating that rivals that of gas burners. This ensures evenly cooked food without the common issues of under or overcooking associated with conventional stovetops.

Safety and Control: Induction cooktops are equipped with sophisticated control systems that automatically shut down the heating element if no cooking vessel is detected or if the vessel is too small. This feature enhances safety by reducing the risk of accidents and energy wastage.

Ease of Cleaning and Maintenance: The design of induction cooktops makes them incredibly easy to clean and maintain. The flat cooking surface doesn't get too hot, preventing food spills from burning and sticking, which makes cleanup a breeze. Heat is generated directly in the cooking vessel, leaving the cooktop surface cooler and safer to touch shortly after cooking.

Overall, the combination of energy efficiency, improved safety, uniform heating, and ease of maintenance makes induction-based cooking an attractive option for both amateur cooks and professional chefs alike.

Figure 3 - Heat is produced only in the vessel and not in the top plate

Simulation using a standard induction cooker coil arrangement

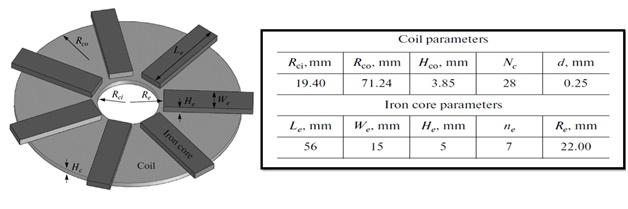

Figure 4 presents a CAD model illustrating a coil and iron core setup suitable for induction cooking applications. This configuration underwent simulation in EMS for SolidWorks, employing AC excitation at a frequency of 24 KHz. Through this process, the coil's inductance was accurately calculated, and the magnetic flux density within the arrangement was effectively visualized, providing valuable insights into the operational dynamics of the induction cooking system. This simulation aids in understanding how the coil and iron core interact under specific conditions, crucial for optimizing the design for efficient induction cooking.

Figure 4 - CAD model of a typical coil used for induction cooking

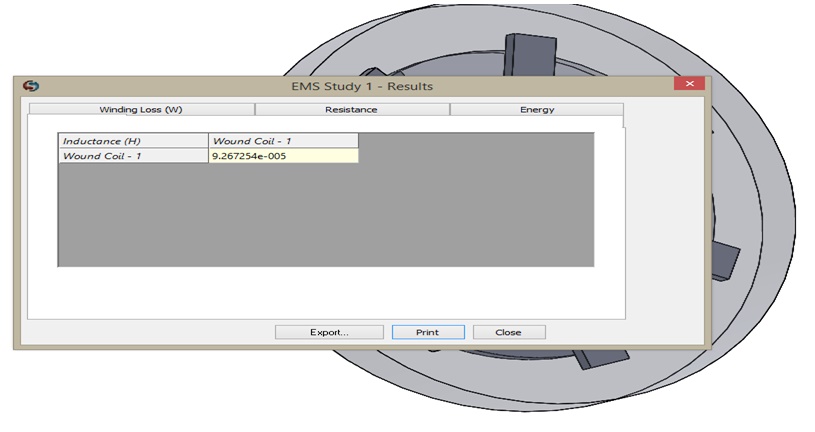

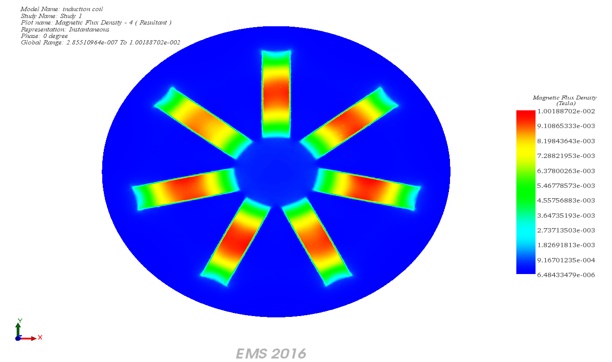

The inductance value determined by the simulation software stood at 92.67 microhenries, showing excellent agreement with the laboratory-measured result of 93.8 microhenries. This close match underscores the accuracy and reliability of the simulation process. Figure 5 illustrates the distribution of magnetic flux density within the coil and iron cores, providing a visual representation of the magnetic field's behavior in the simulated induction cooking setup. This visualization is crucial for assessing the efficiency and effectiveness of the coil and iron core arrangement in real-world applications.

Figure 5 - The plot of magnetic flux density in the coil and the iron cores

Conclusion

The application blog demystifies induction cooking, a technology that leverages electromagnetic induction to heat cookware directly, offering an efficient alternative to conventional cooking methods. By inducing eddy currents in ferromagnetic cookware, it achieves rapid and uniform heating, highlighted by its energy efficiency and safety features. This technology not only ensures faster cooking times but also simplifies cleaning and maintenance, making it a superior choice for modern kitchens. The note emphasizes induction cooking's blend of science and practicality, presenting it as a cornerstone of energy-efficient culinary practices.