Leading the Electromechanical Revolution with EMWorks

Precision Simulation for Advanced Actuators and Solenoids

Efficient, reliable actuators, solenoids, and electromechanical systems are critical to driving innovation in industries such as automotive, aerospace, and precision engineering. EMWORKS provides advanced simulation tools to design and optimize these components, helping engineers achieve superior performance, energy efficiency, and durability. From eddy current brakes to MEMS devices, EMWORKS accelerates development and reduces costs while ensuring the highest standards of reliability.

-

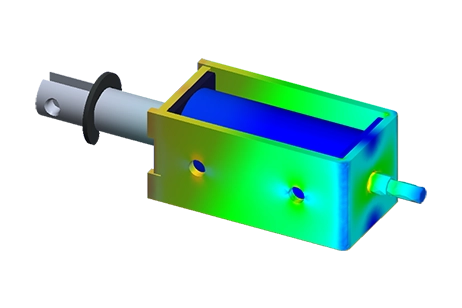

Linear and rotational actuators

Discover EMWorks' electromagnetic design software tailored for linear and rotational actuators. Revolutionize actuator systems and innovation. -

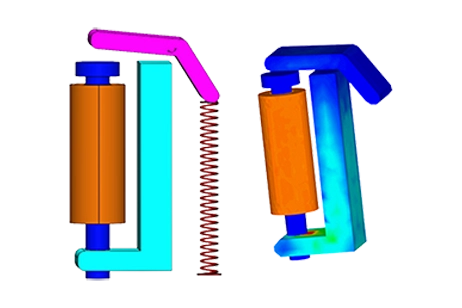

MEMS

Explore EMWorks' electromagnetic design software tailored for MEMS applications. Revolutionize MEMS systems and innovation with our specialized solutions. -

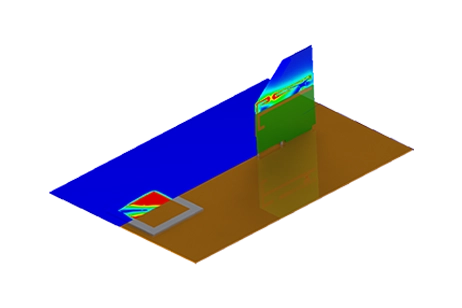

Eddy Current Brakes

Explore EMWorks' electromagnetic design software tailored for eddy current brake applications. Revolutionize eddy current brake systems and innovation.