Innovative Magnetic Simulation Solutions

Harnessing the Power of Magnets with EMWorks Technology

Discover EMWorks' state-of-the-art simulation software for magnets and magnet arrays, designed for precision, innovation, and efficiency in diverse industries.

-

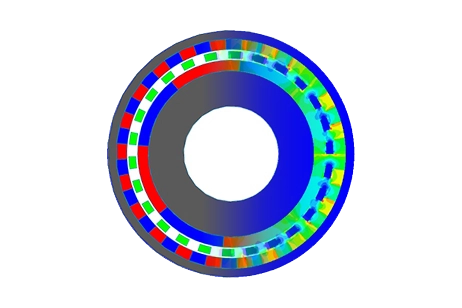

Magnetic Levitation Vehicles

Explore EMWorks' electromagnetic design software tailored for magnetic levitation applications. Fuel innovation and optimize maglev systems with our solutions. -

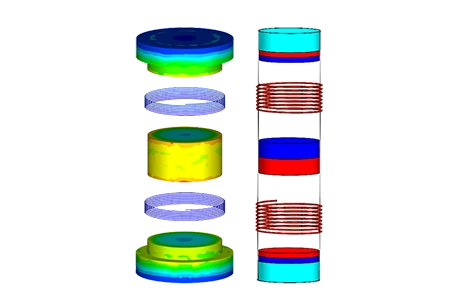

Permanent Magnets

Discover EMWorks' electromagnetic design software designed for permanent magnet applications. Revolutionize magnetic systems and innovation. -

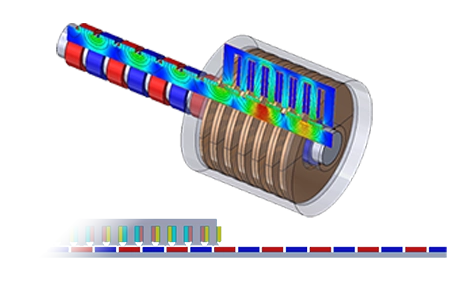

Magnetic Gears

Explore EMWorks' electromagnetic design software tailored for magnetic gears. Revolutionize gear systems and innovation with our specialized solutions.