Innovative Sensor and NDT/NDE Technologies by EMWorks

Pioneering Non-Destructive Testing and Evaluation in Various Industries

Explore EMWorks for superior sensor and NDT/NDE solutions. Our software ensures precision and reliability in material and structural inspection across industries.

-

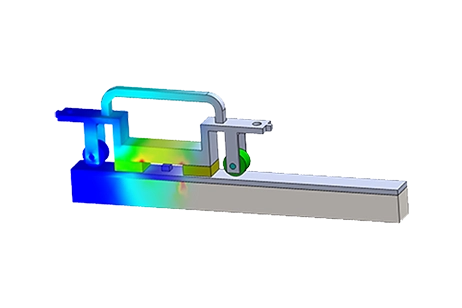

Sensors

Discover EMWorks' electromagnetic design software tailored for sensor applications. Revolutionize sensor systems and innovation with our specialized solutions. -

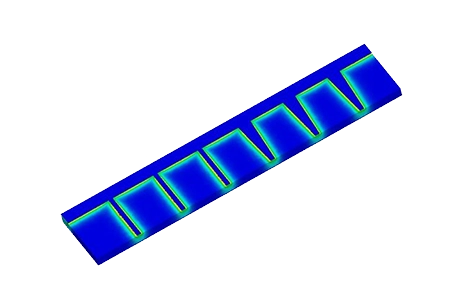

Non-destructive Testing/ Evaluation

Explore EMWorks' electromagnetic design software tailored for NDT/NDE sensor applications. Revolutionize NDT/NDE sensor systems and innovation with EMWorks.